Floating condensation and evaporation consist of allowing the condensation and evaporation temperatures of a refrigeration circuit to fluctuate freely. In this way, these temperatures are not constant all the time, but change as a function of external temperatures and production demands.

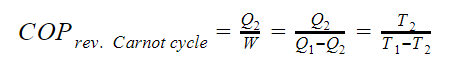

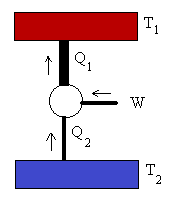

If we analyse a refrigeration cycle or a reversed Carnot cycle from the theoretical point of view of thermodynamics, we can observe that its performance or COP depends only on the temperature of the hot and cold reservoirs (T1 and T2 respectively):

According to this equation, we see that the smaller the temperature difference of the condenser and the evaporator, the greater our performance:

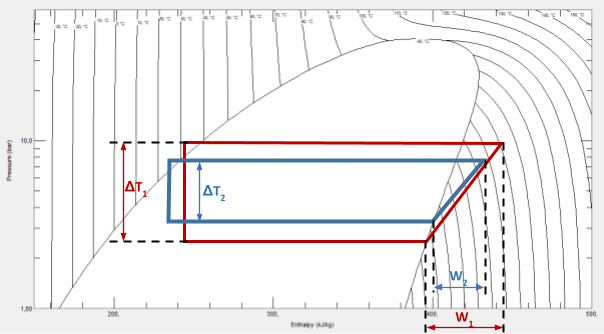

If we analyse it from a more intuitive point of view, we can see that the smaller the temperature difference, the pressure ratio is lower, and the compressor needs to perform less specific work for that pressure difference. Therefore, as the compressor power decreases, the performance increases. This can be clearly seen in the P-h diagram.

With floating condensation and evaporation, we allow the temperatures to adapt to external changes, and in this way, the performance and energy efficiency of our installation will increase.

If we use a floating condensation, the condensation temperature can be reduced if we allow it to adapt to the external temperatures. With this system, if the outside temperature drops, the condensing temperature can be reduced as well.

In the case of floating evaporation, we also let the evaporation temperatures fluctuate depending on the cooling demand.

In order to implement floating condensation and evaporation, we have to install control system based on electronic expansion valves instead of thermostatic valves and variable frequency drives in the compressor. This allow us to adjust the condensation and evaporation temperatures in a more efficient way, as long as the appropriate heat transfer temperature difference is enough to guarantee the demand of our installation.

By implementing these systems, the performance or COP of our refrigeration or HVAC installation can be increased, which translates into energy savings of between 2-3% for each degree of reduction in the temperature difference between condensation and evaporation, approximately.